When the small suction dredge is running, the customer usually asks questions about how to lubricate the the whole small suction dredge. For example, diesel engine, clutch(power take off), sand pump and winch need the engine oil or grease lubrication ? Are there label restrictions or request?

Followed are the Methods on How to Lubricate the Small Suction Dredge

1. How to Lubricate Diesel Engine and Clutch of Small Suction DredgeSmall suction dredge usually has two or three sets diesel engines, The large size diesel engine is matched with sand pump. Medium size diesel engine is for high-pressure water pump and manual hoist, and small size diesel engine is for propelling system. We should carry out the daily maintenance such as filling water, engine oil and grease lubrication.

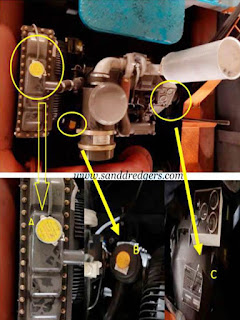

Small suction dredge is equipped with two clutches(also called Power take off), which is an indispensable part of sand pump set. The lubrication system of the clutches requires grease and the universal lithium grease. Before the sand dredger leaves the factory, our assembly engineer will add the grease into the clutches. Therefore, the customer only needs daily maintenance. The grease itself has no volatility and small loss. The equipment can be refilled once a quarter. A thin tube at the label above the clutch can be filled with a grease gun. Use a grease gun to fill in grease. After cleaning the clutch or replacing the fitting, it is recommended to clean the bearing with a special grease cleaning solution and add new grease. The following pictures show different parts of diesel engine need to be filled into which kind of material.

A :Fill water for cooling

B :Fill in engine oil

C: Fill in grease lubrication

D: Fill in water in D

E :Fill engine oil in E

2. How to Lubricate Marine Sand Suction Pump and High Pressure Water Jet Pump in Small Suction Dredge

Both the sand pump and the high pressure water pump are in the form of engine oil lubrication. Since the bearing lubrication requirements are relatively small, 32# or 46# general engine oil lubricants can be considered. The 46# engine oil with relatively high viscosity is suitable for summer conditions or working conditions in high temperature areas. When filling the engine oil, be sure to control the amount of oil. If the oil is pumped in the oil pumping chamber, the oil temperature in the chamber will be too high, or the oil in the engine room will be too low, resulting in insufficient bearing lubrication. The bearing wears too fast and affects the service life of pump set. When the sand pump or water pump is running for about 1000 hours, it should be replaced with new engine.

3. How to Lubricate Manual Winch in Small Suction Dredge

The manual winch is mainly used for lifting sand suction head and pipes, and winch is composed of reducer, roller and hand brake. The lubrication system of the manual hoist is a combination of engine oil lubrication and grease.

The speed reducer of the manual hoist is filled with engine oil. It is recommended to use 32# and 46#. The filling capacity shall be based on the oil gauge of the reducer. On the other side of the manual hoist, one of the bearings needs lubrication, but it is in the form of butter lubrication. There is a small hole in the side end cover, and the grease gun can be used to fill the small hole. The filling cycle is consistent with the clutch.

4. How to Lubricate Propeller System in Small Suction Dredge

The Propeller system is an optional component, mainly used for small suction dredge movement, and the driving mode is diesel engine. The lubrication of the marine propeller machine is engine oil lubrication. The requirements for the lubricating engine oil are not very high. You can use 32# or 46# engine You need to fill the whole cavity before using. If you hear the sound of metal impact, the amount of oil filled is too low.

5. Conclude the Whole small suction dredge Lubrication System

After 100 hours of initial fueling operation, the small suction dredge should replace the new engine oil with the whole dredge. During the normal maintenance period, it is necessary to ensure that the engine oil is completely change but not just replace engine oil. If you see the oil missing, add it again. Note that the impurities in the oil compartment can not be discharged, and the newly added oil will not play the role of lubricating the bearing.

没有评论:

发表评论